3D Printing Metal Market Size, Regional Analysis, and Forecast 2024–2030 (Business Opportunities - Other Business Ads)

USAOnlineClassifieds > Business Opportunities > Other Business Ads

Item ID 2936800 in Category: Business Opportunities - Other Business Ads

3D Printing Metal Market Size, Regional Analysis, and Forecast 2024–2030 | |

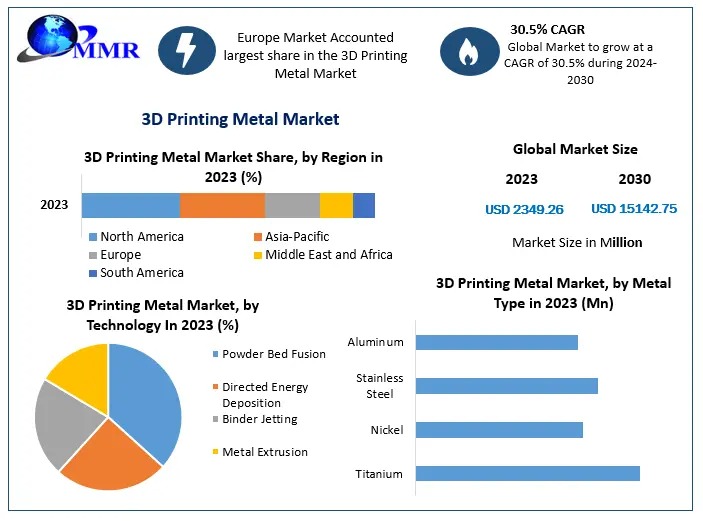

3D Printing Metal Market: A Transformative Era in Manufacturing Innovation Market Estimation & Definition The 3D Printing Metal Market size was valued at US$ 2349.26 Mn. in 2023 and the total revenue is expected to grow at a CAGR of 30.5%,reaching nearly US$ 15142.75 Mn. 3D printing metal, also known as metal additive manufacturing, revolutionizes how complex and intricate structures are created, using technologies such as Powder Bed Fusion, Directed Energy Deposition, and Binder Jetting. These methods enable the production of high-precision parts from materials like titanium, stainless steel, nickel, and aluminum. Ask for Sample to Know US Tariff Impacts on Market @ Sample Link : https://www.maximizemarketresearch.com/request-sample/195/ Market Growth Drivers & Opportunities Several dynamic factors are propelling the 3D Printing Metal Market: Increased Investments: Companies like Mantle Inc. have secured significant funding ($25 million) to advance 3D printing technology, driving commercial scalability and cost-efficiency. Healthcare Revolution: Additive manufacturing is transforming the dental and medical sectors, enabling customized production of crowns, bridges, dentures, and surgical tools. Shift to End-Use Production: Over 50% of businesses now employ 3D printing for final-use products, signaling a monumental shift from prototyping to mass manufacturing. Aerospace and Automotive Demand: Lightweight, precision-engineered components, critical to aerospace and defense sectors, are increasingly manufactured through 3D metal printing, optimizing fuel efficiency and operational performance. This technological wave opens immense opportunities for industries to enhance product customization, reduce lead times, and achieve sustainable manufacturing goals. What Lies Ahead: Emerging Trends Shaping the Future As the industry evolves, several key trends are shaping its future: Healthcare Expansion: Growing adoption of 3D printing in biomedicine for patient-specific implants and surgical devices. Material Innovation: The development of new metal alloys and composites will further extend application possibilities. Integration into Industry 4.0: The synergy of AI, IoT, and additive manufacturing promises smarter, more autonomous production lines. Sustainability Push: 3D metal printing offers reduced material waste compared to traditional methods, supporting global sustainability targets. Segmentation Analysis According to the report: By Form: Powder dominates the market (94% share in 2023), attributed to its critical role in ensuring the quality and precision of the final printed product. Filament remains a smaller, yet growing, segment. By Metal Type: Titanium leads due to its excellent corrosion resistance and durability. Nickel, Stainless Steel, and Aluminum also hold significant shares. By End-Use Industry: Aerospace & Defense leads, given its need for lightweight, strong components. Automotive and Medical & Dental industries are rapidly embracing metal additive manufacturing technologies. Ask for Sample to Know US Tariff Impacts on Market @ Sample Link : https://www.maximizemarketresearch.com/request-sample/195/ Country-Level Analysis: USA and Germany USA: As a technology frontrunner, the U.S. is heavily investing in 3D printing research and commercialization, especially in defense, healthcare, and aerospace sectors. With strong government backing and private sector innovation, the U.S. remains a global leader in metal additive manufacturing. Germany: Germany is at the heart of Europe's 3D printing boom, bolstered by its renowned manufacturing and engineering excellence. The integration of 3D printing into Germany’s "Industry 4.0" vision fuels its dominance, particularly in automotive and aerospace applications.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target State: US Virgin Isles Target City : US Last Update : Apr 24, 2025 6:04 AM Number of Views: 49 | Item Owner : Nilam Contact Email: Contact Phone: (None) |

| Friendly reminder: Click here to read some tips. | |

USAOnlineClassifieds > Business Opportunities > Other Business Ads

© 2025 USAOnlineClassifieds.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com

2025-09-16 (0.454 sec)