Free Classifieds at USAOnlineClassifieds.com - View Item Content by ID 1860323

USAOnlineClassifieds > Automobiles & Vehicles > Auto Parts & Services > Item ID 1860323

Item ID 1860323 in Category: Automobiles & Vehicles - Auto Parts & Services

Cannot view this item. It could be pending, expired or deleted.

Below item is randomly selected from the same category and may have similar content.

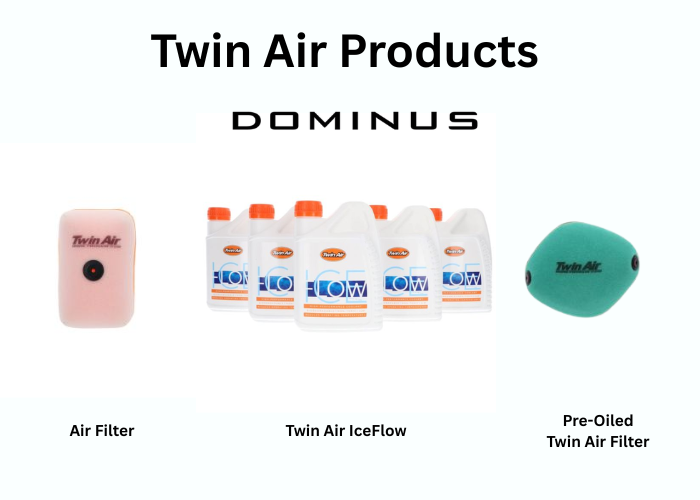

Twin Air Products - Dominus | |

Twin Air is the world-leading manufacturer of foam-type air filters and protective filtration products, boasting over 40 years of experience in the field. Their product range covers high-performance air filters as well as radiator sleeves, fuel filters, oil filters, fuel-tank foam and dust covers, giving off-road and motocross riders reliable and effective engine protection. Distributed in the U.S. by Dominus Corporation via channels such as Western PowerSports, Tucker Distributing and Parts Unlimited, Twin Air products combine long-standing expertise with broad availability.  | |

| Related Link: Click here to visit item owner's website (0 hit) | |

| Target State: All States Target City : All Cities Last Update : Nov 25, 2025 7:52 AM Number of Views: 48 | Item Owner : Dominus Contact Email: Contact Phone: 800-749-2890 |

| Friendly reminder: Click here to read some tips. | |

USAOnlineClassifieds > Automobiles & Vehicles > Auto Parts & Services > Item ID 1860323

© 2025 USAOnlineClassifieds.com

USNetAds.com | GetJob.us | CANetAds.com | UKAdsList.com | AUNetAds.com | INNetAds.com | CNNetAds.com | Hot-Web-Ads.com

2025-11-26 (0.586 sec)